Introduction

If you had a formal education that touched even a little bit of composite materials in the course, you will immediately be able to recall what these amazing materials can do. For others, Composite materials, as the name suggests, are materials that are composed of two or more different kinds of materials.

In a simple case think of your body, which is, in a broad sense, a combination of skin material and bone material. These materials are designed to take advantage of the contrasting properties of, say two different materials. For simplicity’s sake, skin is soft and bone is hard. The bone gives body a solid structure, while the skin and muscle tissues enables this hard skeleton to make fluid movements – flex or bend – and still be together.

Individually the materials that make up a composite material are not very capable. But when they come together, composite materials can blow your mind. To appreciate how this simple coming together of two humble materials can create a super material, and to appreciate the mind blowing properties it can have, let us first look at what most of us have heard of – “Carbon Fiber”. We will get into the more mind bending aspect of composites after that.

Carbon Fiber Reinforced Polymers (CFRP)

Now carbon fiber itself isn’t a composite material. As the name suggests, it is a fiber of carbon. The fiber is composed of strands of carbon each of which are much thinner than a single human hair. Hundreds of these come together to form a thicker fiber. This fiber can be woven to make sheets or the carbon fiber itself can directly be used in a composite material.

Like an average fiber, carbon fiber and sheets woven out of it behave almost like threads and cloth, respectively. They can’t hold themselves into a rigid structure. But the amazing difference between average fibers and carbon fibers is that carbon fiber is extremely light as it is made of only carbon – which is a very light element. See, how early it comes in the periodic table – Find it at number 6 and its atomic weight is just 12 units.

Another amazing property of their’s is that these fibers have a very high tensile strength. That means it is very hard to pull and break them.

Carbon fibers and other directly derived products certainly have a wide variety of applications and are used to make things like high-end racing gloves, micro-electrodes or heated jackets. Let’s keep the discussion of all that for some other time. Right now, we are interested in composites.

Most of the time when people use the word “carbon-fiber”, they actually mean carbon fiber reinforced polymer (CFRP) – a composite material!

A simple CFRP panel can be made by putting down a sheet of carbon fiber (CF) on a base of thermosetting resin like epoxy, putting some resin on it, and another sheet of CF and so on. In the end you have a rigid panel of CFRP. In such panels, the resin is called the matrix and the fiber is the reinforcing material. This is how it can be done at home – to give you a picture of what the process looks like:

Such panels are expensive to make but have such amazing properties that they are used in all sorts of applications where light weight and high tensile strength is of great importance. Racing cars, bikes, adventure sport gear, airplanes and what not!

Such types of Fiber + Matrix composites are many. Like glass fiber reinforced, or aramid fiber reinforced and so on. By finding a sweet spot, estimating how good you want the properties to be and how much you can spend, you can find the combination of matrix and fiber that suits your application and budget.

But composites are many

If you look around, you’ll notice that most things around you are composites! It is quite rare for a single material to supply the desired properties at a desired price in today’s world.

Concrete is the most common composite. That’s because concrete in its simplest form is basically a mixture of loose stones and cement. Where, the loose stones are the reinforcing material and the cement acts as the matrix. We have whole jungles of concrete in every city. Composites are everywhere.

In the forest, wood is a good example of a naturally occurring composite. It is made up of cellulose fibres in a lignin and hemicellulose matrix.

Other composites can be reinforced by particles, chopped strands, fibers, laminates, fabric etc. Composites are amazing, and if they interest you too, you can learn much more about them in this PDF digest – Download. Or of course, you could also go to wikipedia to learn more.

Because now with a basic understanding of composites, we can move on to the mind bending part I really want to talk about.

Mechanically Stabilized Earth (MSE)

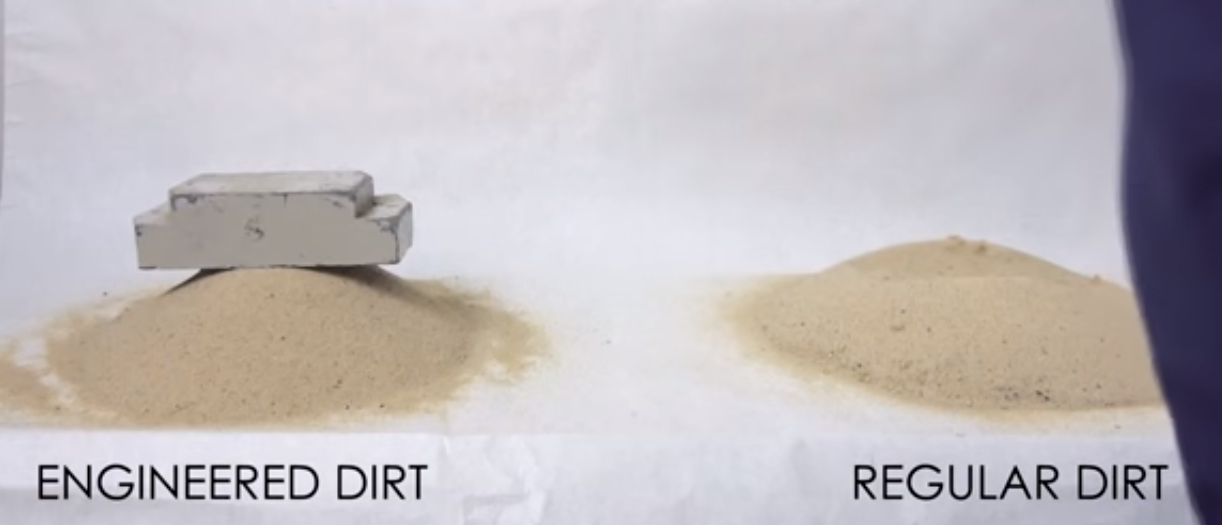

If you take a handful of sand and try to make a block out of it, you probably won’t even be able to make it. All you’ll accomplish doing is making a conical heap of sand. We all know, sand can’t hold its structure under its own weight. The individual particles of sand aren’t held together by anything.

You may succeed in constructing something that looks like a block if you try to bind it by using a little amount of water. That is what little kids do at the beach to make weak castles of sand.

Whatever you do, your block (or castle) won’t be able to bear a lot of weight that you put on it. If you try to stand on it, the block would not be able to support your weight without collapsing into a heap of sand.

After this try a simple experiment. Lay down an inch of sand, put a sheet of paper on it and then again a layer of sand and paper and so on – A similar process to that of making a CFRP we saw above. After a couple of sheets, say 15 sheets of paper and 15 inches of sand you will have a decently thick block of sand in front of you. You can probably even stand on it without destroying the block. It is amazing how much difference just 15 sheets of paper can make.

Enough number of sheets can even support the weight of a big car.

Rather than using many many sheets of paper, you could use a fewer number of much stiffer reinforcements such as steel grids or stiff fiber glass mesh. For an experiment you could compare the weights different blocks made up of equal number of sheets of different materials can bear. You can cut up old cotton t-shirts and use that as a reinforcing material. Or plastic bags, or aluminum foil. The choices are endless.

Even when the weight of a car couldn’t make the block collapse, we naturally had to turn to the hydraulic press. It is estimated that it takes about 9000 pounds of weight to destroy the block of sand made from glass fiber mesh reinforcement. This load bearing capacity can easily be engineered by carefully selecting the reinforcing material, retaining walls, a different kind of soil etc. That, my friend, is Mechanically Stabilized Earth (MSE) Here is the hydraulic press crushing the same block.

Why don’t we use this a lot for construction purposes, you ask? We do!

MSE for construction

MSE doesn’t fail catastrophically. That means it doesn’t break like a ceramic cup, it breaks (or fails) slowly. It first deforms and gives you a warning before it fails. That makes it a great material to use for large construction projects.

Elevated expressways which appear to be made up of walls of repeating concrete panels like shown in this picture are actually just retaining walls for such mechanically stabilized earth. These panel contains a huge amount of such earth stabilized using reinforcing materials.

For large construction projects the choice of reinforcement material varies from sheets of high density polyethylene (HDPE) sheets, a mesh of steel rods, polyester sheets, geogrids and geosynthetic materials.

The main point for using MSE for filling up the retaining walls is to offer a very cheap construction material with a lot of volume – dirt. Which is reinforced by a relatively lesser amount of the expensive part of the composite – Steel rebar mesh etc.

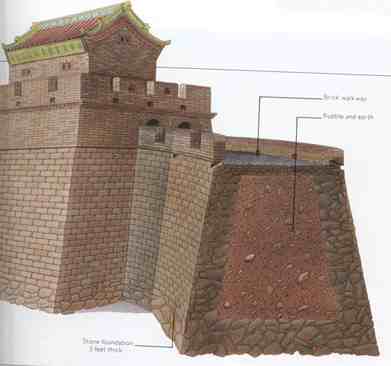

The construction of great wall of China

The great wall of china was built more than two thousand years ago. And in the construction of it, sand was used to fill the huge structure, several meters tall. Now, sand doesn’t stick to each other and the ancient Chinese knew that. So they used willow and reed to layer the sand inside. They basically made MSE with organic reinforcing material, just like modern express ways. That’s some ancient wisdom right there.

The great wall of china was built more than two thousand years ago. And in the construction of it, sand was used to fill the huge structure, several meters tall. Now, sand doesn’t stick to each other and the ancient Chinese knew that. So they used willow and reed to layer the sand inside. They basically made MSE with organic reinforcing material, just like modern express ways. That’s some ancient wisdom right there.

Today we use inorganic reinforcing material (as mentioned above) mainly because organic reinforcing materials organic reinforcing materials can easily get exposed to biological forces which tend to break down the organic matter as food, thus weakening the structure somewhat faster than other more durable materials.

Rammed earth buildings

An ancient method of making buildings using sustainable building materials is the little known concept of rammed earth buildings. There are a number of historical records that indicate walls, foundations, and floors were built using natural raw materials such as rammed earth. The common reinforcing materials used for such endeavors in the past were bamboo, wood, straw, root systems etc. Read more…

MSE is also known as Bewehrte Erde in German.

So the next time you go to the beach I hope this lesson helps you to build much stronger castles with immense amount of load bearing capacity.